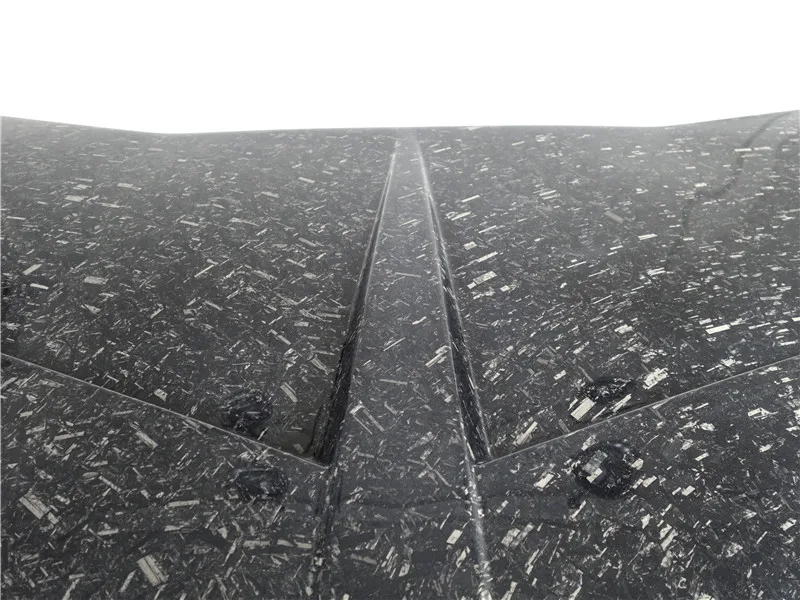

Trade Assurance Forged Carbon Fiber Fit For 2014-2019 Huracan LP610-4 & LP580-2 Coupe Spyder 1016 Style Front Hood Bonnet

- Portshanghai/ningbo

- Payment TermsWestern Union,T/T,MoneyGram,Paypal

- Supply Ability50 Piece/Pieces per Month

- Condition100% Brand-New

- Product NumberYCLB610019SDZCF

- Place of OriginChina (Mainland),Zhejiang China

- External Testing CertificationISO9000

- Car FitmentLamborghini

- ColorBlack

- Service24 Hours Customer Service

- Model NumberLP610-4 & LP580-2

- Brand NameYachant,Yachant

- FunctionDecoration+Protection

- Year2014-

- QualityHigh-Quality

- ModelHuracan

- Fitment100% Fitment

- Packaging DetailFoam and bubble wrapping, cupboard box carton

Detailed drawings:

FEATURE:

Vacuum Infusion Carbon

3K Twill Carbon Weave in Glossy Finish by Default

Light Weight

Perfect Fitment

Aerodynamic

Better Looking

Very easy to install, recommend install on body street shop

Company Introduction

Wenzhou Yachant Trading Co., Ltd. was founded in 2010, specialized in production and export business. OEM orders are welcome. We provide car parts for customers from all over the world.

We have connections with a lot of manufacturers in China. "To maintain quality of products and provide best customer services" is our principle. We know that good relationships with customers are the significant driving force of our company.

We provide OEM and ODM service of fiberglass and carbon fiber products, ...

Wenzhou Yachant Trading Co.,Ltd. was founded in 2010, specialized in production and export business. OEM orders are welcome. We provide car parts for customers from all over the world.

We have connections with a lot of manufacturers in China. "To maintain quality of products and provide best customer services" is our principle. We know that good relationships with customers are the significant driving force of our company.

We provide OEM and ODM service of fiberglass and carbon fiber products,as well as our air conditioning systems. No matter how difficult the production is, we will always try our best to meet customers' needs.

Thanks for visiting our website:www.yachant.com

If you have any inquiry, please feel free to let us know by calling us.

Our phone number:0086-577-88903881/88903887

Payment:

We accept below payment:

![]()

If buyer have any question for the payment, please let us know.

The price not include any custom duty or other tax.

Shipping:

We use the main delivery company is as below:

We normally will dispatch your order within 2-10 working days depends on stock level, as soon as the order is shipped, we will list the tracking number on your order detail page, if there is any problem regarding to the shipping, please feel free to contact us.

Below shows the estimate delivery time for different courier:-

- FedEx: 7 to 10 working days

- UPS: 7 to 10 working days

- EMS: 10-14 working days

- DHL: 10-14 working days

- China post: 15-21 working days

- Hongkong post air mail: 15-20 working days

Delay is possible and depends on your local custom & postal services. Sometimes custom will hold the order for random check, you also contact your local postal services to see if there is any international incoming mail.

Terms & return:

guarantee 100% satisfaction on our products, and top notch customer services. ALL SALES FINAL, No

refund are offered. Item be returned/exchanged only if the items are found defected or wrong item on

arrival. If item need to be exchanged, items must be returned within 7 days from the date of authorized for

exchange.All presumed defective or wrong items must obtain an authorization before returing.Any returned package without authorization will put on hold or refused.Buyer is responsible for return shipping cost and insurance.Please note that shipping and handling are not refundable

Contact US:

Please use the button "Contact Now" , or use Trademanager software to contact us, we would reply you in the first time as soon as we got your message.

Feedback:

We are very concern about all buyer purchasing feeling in our store, any of your opini on or suggestion is very important for our development, if you are going to leave Neutual or Negative feedback, please do not hesitate to contact us, We appreciate highly if buyer leave us positive feedback.

Take a Look

|

Forging composite technology is jointly developed by the world's largest golf tool manufacturer Callaway and Lamborghini's advanced composite structure laboratory in Seattle, USA. This technology was applied to the caraway club called Diablo octane and the Lamborghini Sesto Elemento concept car respectively.

At the 2010 Paris auto show, with the release of the Sesto Elemento concept car, Lamborghini officially announced its forged composite technology and applied it to a large number of key parts.

The dry and wet carbon fiber parts introduced before are made of long carbon fiber woven cloth, and the obvious texture of carbon fiber weaving can be seen. The forged carbon fiber is forged with short cut carbon fiber, which is similar to SMC process.

Because the short cut carbon fiber can use leftover materials or recycled materials, the cost of raw materials will be lower. But its strength is lower than that of continuous carbon fiber.

The traditional carbon fiber production process mainly includes fiber spinning, thermal stabilization, carbonization and graphitization. In addition, it takes more than 24 hours to bake the separated resin and carbon fiber cloth under high pressure. The production time of forged carbon fiber is significantly shortened. The chopped carbon fiber is combined with resin and sandwiched between two steel molds, and then heated under the pressure of 1200-1500psi for 3 minutes. The significant shortening of the production cycle means that the production cost of forged carbon fiber will be greatly reduced.

Another advantage is that after short cut carbon fiber is mixed with resin, it has good fluidity under the action of high pressure and can form parts with complex structure.

Because of the small proportion of carbon fiber and excellent mechanical properties of materials, it has always been one of the materials pursued by the automotive industry. Why is it not popularized in a large area and only favored by luxury cars? There are several reasons:

First of all, because the manufacturing process of carbon fiber is very expensive, carbon fiber needs to be baked or deposited at high temperature in inert gas by organic fiber or small molecular organics, such as hydrocarbons and aromatics, and finally carbonized to form carbon fiber.

Secondly, the manufacturing process of carbon fiber composites is complex and the production cycle is long, resulting in high product cost. At present, the mature production methods of carbon fiber composites include the following.

Winding method: you can simply understand that the composite material is wound on a core mold like a column to form a tubular product. For example, the carbon fiber frames of some high-end mountain bikes are produced by this process.

Hand paste molding: wood mold or soft mold, which is a method of manually coating materials on the mold surface to finally obtain products. It is impression that some wind power blades are made by this process.

Resin transfer molding (RTM): you can understand that first lay the fiber sheet into the mold, then close the mold, and then inject the resin into the mold to produce cross-linking and curing reaction, and finally form the product.