Ready Ship To USA Trade Assurance Dry Carbon Fiber Shift Paddle Fit For 2006-2015 V8 V12 Vantage &S &DB9 &DBS & Rapide

- PortShanghai/Ningbo

- Payment TermsT/T,Western Union,MoneyGram,Paypal

- Supply Ability5 Piece/Pieces per Month

- Condition100% New

- Warranty3 Months

- Place of OriginZhejiang China

- PositionFront

- Car FitmentAston Martin

- OE NO.Unknow

- Service24 Hours Customer Service

- Material TypeDry Carbon Fiber

- CertificationYes

- Product numberYCASMTVT016LDCF

- Car ModelV8 V12 Vantage

- Brand NameYachant

- FunctionDecoration

- TypeInstallation

- Year2010-2016,2009-2016

- Advantage10 Years Experience

- QualityHigh-Quality

- ModelV8 Vantage,V12 Vantage

- FitmentExcellent

- ShippingDHL TNT UPS FEDEX EMS Air Sea

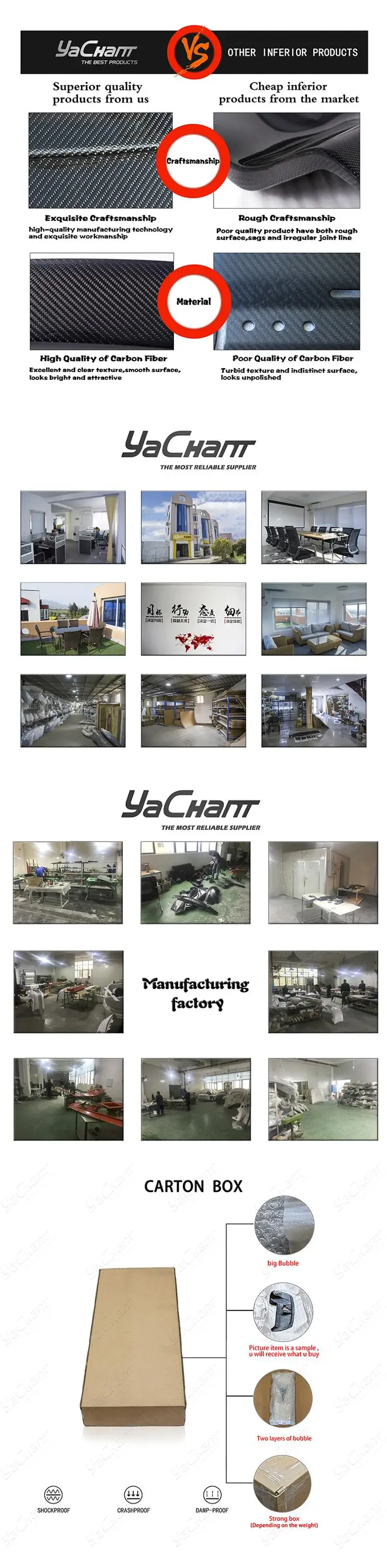

- Packaging DetailFoam and bubble wrapping, cupboard box carton

Detailed Drawing:

Ready to Ship to USA. Available in Stock at our USA Warehouse

Feature:

Dry Carbon by AUTOCLAVED

3K Twill Carbon Weave in Glossy Finish by Default

Light Weight

Perfect Fitment

Aerodynamic

Better Looking

Very easy to install, recommend install on body street shop

Company Introduction

Wenzhou Yachant Trading Co., Ltd. was founded in 2010, specialized in production and export business. OEM orders are welcome. We provide car parts for customers from all over the world.

We have connections with a lot of manufacturers in China. "To maintain quality of products and provide best customer services" is our principle. We know that good relationships with customers are the significant driving force of our company.

We provide OEM and ODM service of fiberglass and carbon fiber products, ...

Wenzhou Yachant Trading Co.,Ltd. was founded in 2010, specialized in production and export business. OEM orders are welcome. We provide car parts for customers from all over the world.

We have connections with a lot of manufacturers in China. "To maintain quality of products and provide best customer services" is our principle. We know that good relationships with customers are the significant driving force of our company.

We provide OEM and ODM service of fiberglass and carbon fiber products,as well as our air conditioning systems. No matter how difficult the production is, we will always try our best to meet customers' needs.

Thanks for visiting our website:www.yachant.com

If you have any inquiry, please feel free to let us know by calling us.

Our phone number:0086-577-88903881/88903887

Payment:

We accept below payment:

![]()

If buyer have any question for the payment, please let us know.

The price not include any custom duty or other tax.

Shipping:

We use the main delivery company is as below:

We normally will dispatch your order within 2-10 working days depends on stock level, as soon as the order is shipped, we will list the tracking number on your order detail page, if there is any problem regarding to the shipping, please feel free to contact us.

Below shows the estimate delivery time for different courier:-

- FedEx: 7 to 10 working days

- UPS: 7 to 10 working days

- EMS: 10-14 working days

- DHL: 10-14 working days

- China post: 15-21 working days

- Hongkong post air mail: 15-20 working days

Delay is possible and depends on your local custom & postal services. Sometimes custom will hold the order for random check, you also contact your local postal services to see if there is any international incoming mail.

Terms & return:

guarantee 100% satisfaction on our products, and top notch customer services. ALL SALES FINAL, No

refund are offered. Item be returned/exchanged only if the items are found defected or wrong item on

arrival. If item need to be exchanged, items must be returned within 7 days from the date of authorized for

exchange.All presumed defective or wrong items must obtain an authorization before returing.Any returned package without authorization will put on hold or refused.Buyer is responsible for return shipping cost and insurance.Please note that shipping and handling are not refundable

Contact US:

Please use the button "Contact Now" , or use Trademanager software to contact us, we would reply you in the first time as soon as we got your message.

Feedback:

We are very concern about all buyer purchasing feeling in our store, any of your opini on or suggestion is very important for our development, if you are going to leave Neutual or Negative feedback, please do not hesitate to contact us, We appreciate highly if buyer leave us positive feedback.

Take a Look

|

Carbon fiber, which is familiar and unfamiliar, is often heard. It is a high-performance material. It has both the hard inherent characteristics of carbon materials and the soft processing characteristics of textile fibers. It is known as the king of materials.

High end materials often used in aircraft, rockets and bulletproof vehicles. The application of carbon fiber in cars was first used in F1 racing cars. Now it is also used in civil cars. It is painted with black paint and deliberately exposes the carbon fiber components with black woven patterns. When it is turned on, it is pulling the wind.

Fiber material is super light and soft. How can it be made into solid auto parts? How to reduce the cost of carbon fiber used in cars?

The best carbon fiber technologies are Japan and the United States. Japan is the country with the largest carbon fiber production in the century, and Japan's carbon fiber production capacity accounts for half of the world.

In 1880, Edison invented carbon fiber. Yes, Edison invented the light bulb. Carbon fiber was found when testing the filament. After more than 100 years of development, BMW used carbon fiber on I3 and I8 in 2010, opening the application of carbon fiber in cars.

Manufacturing process of carbon fiber

Wire drawing: the raw material is heated. It is a reinforcing material.

The reinforcing materials used for winding are mainly various fiber yarns: such as alkali free glass fiber yarn, medium alkali glass fiber yarn, carbon fiber yarn, high-strength glass fiber yarn, aramid fiber yarn and surface felt. Resin matrix, and various fillers. Extruded into gel shaped filaments, plastic fibers are composed of thousands of filaments.

Stability: after 400 degrees of heating and oxidation, the thermoplastic macromolecules are converted into heat-resistant structure. Make it incombustible at high temperature, keep the fiber shape, and carbonize in a stable state. Heat 1000-2000 degrees to drive away non carbon atoms, turn black with high-temperature oxidation, and then combine the carbon atoms on the fiber through the carbonization furnace.

Graphitization: parallel filaments pass through the charged corrosion surface to better absorb the resin. Hundreds of fibers are used to form a fiber net. The resin coating and the fiber net enter the machine at the same time to heat the resin and adsorb it on the fiber net. The resin infiltrates into the fiber net through extrusion. After cooling, the liquid resin becomes a gel.

The principle is like pasting a piece of paper completely into a thick pile of paper, and the pile of paper will become strong.

When it comes to carbon fiber, I will think that it is strong, lightweight and expensive (compared with steel and aluminum products). For example, it is used in high-end products such as F1 racing cars, but now it is used in civil cars. In fact, carbon fiber is a general term of materials in a broad sense, and there are many derived composite materials.

The cost of high-temperature heat treatment is also different for different composites according to the carbonization rate, so the price of different carbon fiber materials will vary greatly. With the development of technology, the scope of application becomes larger, more capital investment and the maturity of recycling technology, the cost of carbon fiber will be further reduced. Carbon fiber composites will be more and more used in automobiles.

Therefore, carbon fiber will be more and more widely used in the field of automobile. In the future, the emission of automobile will be lower and lower, and the automobile itself will be more and more "high carbon". Two technologies that will subvert cars in the future are carbon fiber, new materials and intelligence.