Dry Carbon Fiber 2021-2023 BMW G80 M3 G82 M4 OD Style Front Fender For G80 M3 G82 M4

- Portshanghai/ningbo

- Payment TermsT/T,Western Union,MoneyGram,PAYPAL

- Supply Ability50 Piece/Pieces per Month

- Condition100% Brand-new

- Warranty3 Months

- Place of OriginZhejiang China

- Product NumberYCBMWG8M008SDCF

- Positionleft&right

- SizeStandard Size

- Car FitmentG80 M3 G82 M4

- OE NO.Unknow

- MaterialDry Carbon Fiber

- FeatureFactory-direct

- CertificationYes

- Brand NameYachant

- FunctionDecoration+Protection

- Year2021-2023

- Advantage10 Years Experience

- QualityHigh-Quality

- Fitment100% Fitment

- Packaging DetailFoam and bubble wrapping, cupboard box carton

Detailed drawing:

FEATURE:

High Quality Dry Carbon Material

Light Weight

Perfect Fitment

Better Looking

Very easy to install, recommend install on body street shop

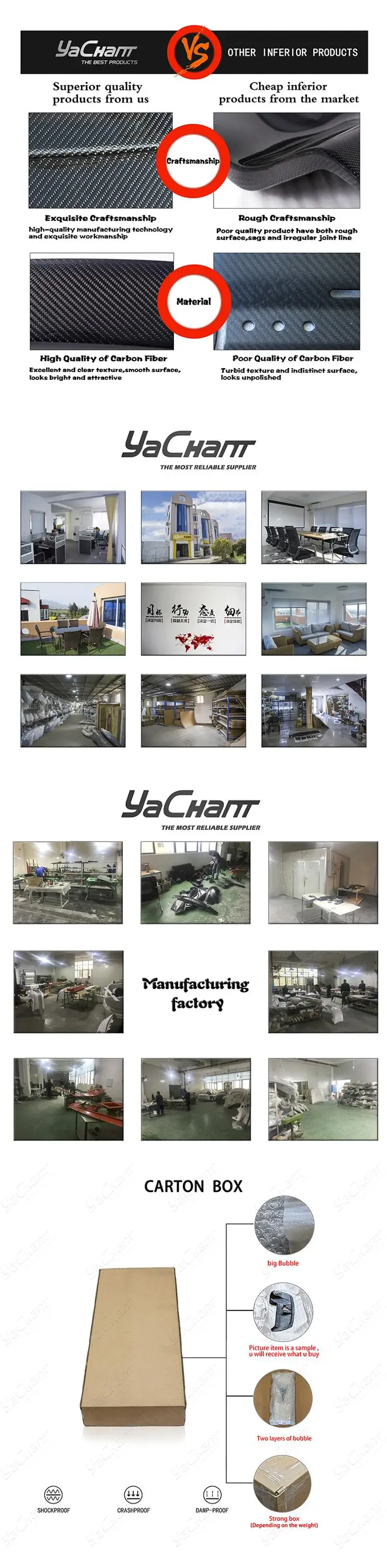

Company Profile

Payment method

Payment method

Comparison between dry carbon and wet carbon

The manufacturing methods and prices of dry carbon fiber and wet carbon fiber are different. Dry carbon fiber is more expensive, with more complex manufacturing processes and higher manufacturing costs. The comparison between the two is as follows:

1. Carbon fiber:

(1) Carbon fiber is a material commonly used in high-performance sports cars and racing cars, and it is generally not found in most civilian vehicles. Carbon fiber is lightweight and has high strength, which is naturally popular among many supercar manufacturers.

(2) There are many supercars that are mostly made of carbon fiber.

(3) Many car enthusiasts will modify their cars with carbon fiber engine covers, which have high strength and can reduce the weight of the front end.

2. Dry carbon fiber:

(1) Dry carbon fiber has less residual resin during manufacturing, resulting in higher strength components made from such broken fibers. The content of tree wax in wet broken fibers is higher, and the cost of making such carbon fibers is relatively low.

(2) There are many counterfeit carbon fiber components on the market, which are only covered with a layer of imitation carbon fiber stickers.

Differences between dry carbon and wet carbon

1、 Different raw materials

Dry carbon is made from chemical fibers such as polypropylene as the substrate, and resin is added under high temperature and pressure. Carbon fiber, on the other hand, is prepared from raw materials such as polypropylene and polyamide at high temperatures to form a mixed fiber, which is then produced through high-temperature graphitization reaction.

2、 Different processing techniques

The processing process of dry carbon includes manual production and mechanical molding, and the surface needs to be polished, but the surface quality after molding is good. The processing of carbon fiber requires multiple process steps such as drawing and sheet composite, resulting in poor surface finish.

3、 Different performance

Dry carbon has advantages such as high rigidity, high wear resistance, and low thermal expansion, and the finished product exhibits excellent strength and stability. However, dry carbon has poor bending, impact resistance, and is prone to fracture. Carbon fiber, on the other hand, has excellent flexibility and impact resistance, exhibiting excellent fatigue resistance and lightweight properties.

4、 Different uses

Due to the advantages of high rigidity and wear resistance, dry carbon is mainly used in high demand fields such as automobiles, aviation, aerospace, and oceans. Carbon fiber is used in sports equipment, composite materials, and other applications due to its excellent flexibility and impact resistance.

In summary, dry carbon and carbon fiber each have unique characteristics and advantages, and have different applications and advantages in different fields. Therefore, when selecting materials, it is necessary to comprehensively consider and analyze according to the actual application needs.