Carbon FIber 2019-2022 Toyota GR Supra MK V A90 A91 TMS Style Front Lip For Supra MK V

- Portshanghai/ningbo

- Payment TermsT/T,Western Union,MoneyGram,PAYPAL

- Supply Ability50 Piece/Pieces per Month

- Condition100% Brand-new

- Warranty3 Months

- Place of OriginZhejiang China

- Product NumberYCTYTSPR043LCF

- PositionFront

- SizeStandard Size

- Car FitmentSupra MK V A90 A91

- OE NO.Unknow

- MaterialCarbon Fiber

- FeatureFactory-direct

- CertificationYes

- Brand NameYachant

- FunctionDecoration+Protection

- Year2019-2022

- Advantage10 Years Experience

- QualityHigh-Quality

- Fitment100% Fitment

- Packaging DetailFoam and bubble wrapping, cupboard box carton

Detailed drawing:

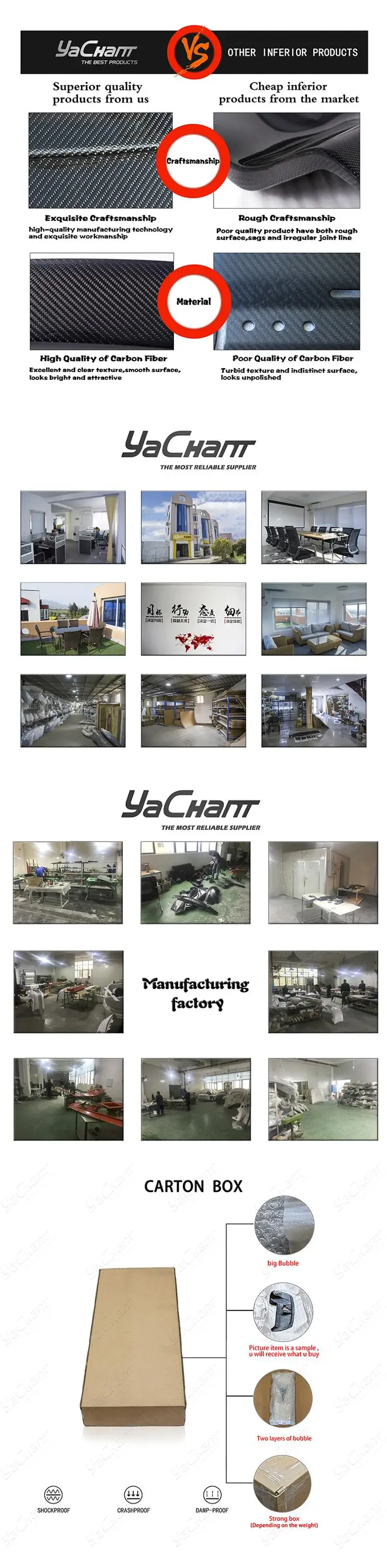

| FEATURE: |

| High Quality Carbon FIber by Vacuum Infusion |

| Light Weight |

| Perfect Fitment |

| Aerodynamic |

| Better Looking |

| Very easy to install, recommend install on body street shop |

What is the use of carbon fiber for automobiles?

After the application of carbon fiber in automobiles, the most obvious benefit it brings to automobile manufacturing is the lightweight of automobiles, and the most direct impact is the improvement of energy conservation, acceleration, and braking performance. Generally speaking, a 10% reduction in vehicle weight, a 6-8% reduction in fuel consumption, a 5-6% reduction in emissions, an 8-10% improvement in 0-100km/h acceleration, and a 2-7m reduction in braking distance.

The application of carbon fiber in the automotive field began with racing cars and has been widely cited in civil vehicles in recent years. The carbon fiber components coated with varnish and intentionally revealing deep black woven patterns are no longer just for the sake of looking stylish, but the "high carbon" wind is getting stronger and stronger. Carbon fiber is a new type of fiber material with high strength and high modulus fibers with a carbon content of over 95%. It is a microcrystalline graphite material obtained by stacking organic fibers such as flake graphite microcrystals along the axial direction of the fibers and undergoing carbonization and graphitization treatment. Carbon fiber is' soft on the outside and hard on the inside ', with a lighter weight than aluminum metal, but higher strength than steel. It also has corrosion resistance and high modulus characteristics, making it an important material in national defense, military industry, and civil use. It not only possesses the inherent characteristics of carbon materials, but also has the flexibility and processability of textile fibers, making it a new generation of reinforcing fibers. Generally, the density of carbon fiber is 1750 kg/m3. Such low density makes it widely used in large aircraft, such as the A350 and A380 of Airbus, and the Boeing 787 Dreamliner use carbon fiber composites to reduce fuel consumption. In addition, the blades of large wind turbines, as well as the bodies of racing cars and high-end bicycles, are important factors in the increasing demand for carbon fiber composite materials. Moreover, carbon fiber has many excellent properties, such as high axial strength and modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non oxidizing environment, good fatigue resistance, specific heat and conductivity between nonmetal and metal, small coefficient of thermal expansion and anisotropy, good corrosion resistance, and good X-ray transmission. Good conductivity and thermal conductivity, good electromagnetic shielding, etc.

The functions of carbon fiber for automobiles are as follows:

1. It is understood that carbon fiber is a high-strength and high modulus fiber material with a carbon content of over 90%, which is widely used due to its excellent properties. In fact, carbon fiber composite materials have begun to be widely used in various industries, including airplanes, high-speed trains, and automobiles in the field of transportation, as well as wind turbines in the energy field. In addition, a large part of them are also used in sports equipment and other industries, such as golf clubs, fishing rods, and other sports products;

2. Of course, with the development of lightweight in the automotive industry, the application of carbon fiber materials in the automotive field is also increasing. As is well known, new energy vehicles have entered a stage of rapid development, and one of the biggest obstacles for consumers towards pure electric vehicles now should be the issue of travel anxiety. In order to improve the driving range of pure electric vehicles more effectively, the lightweight of the body is crucial;

3. In new energy vehicles, hydrogen fuel cell vehicles are known as truly zero emission environmentally friendly vehicles. However, a major issue with these vehicles is the safety of hydrogen, and carbon fiber materials can also play a crucial role. Jiang Shicheng mentioned that high-pressure gas storage tanks used to store hydrogen can use carbon fiber materials, which will better ensure the safety of gas storage tanks.